Precision Assembly

| E-Mail: | stucki@match.uni-hannover.de |

| Team: | Martin Stucki, Rolf Wiemann, Niklas Terei, Lars Binnemann |

| Year: | 2018 |

| Funding: | basic funding |

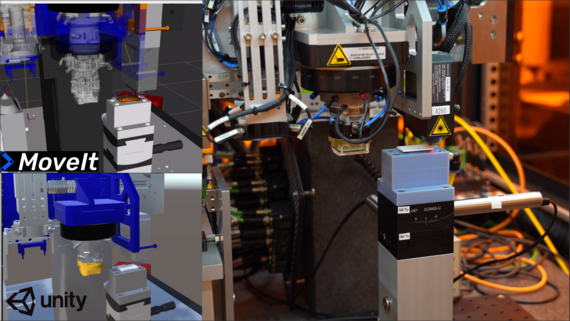

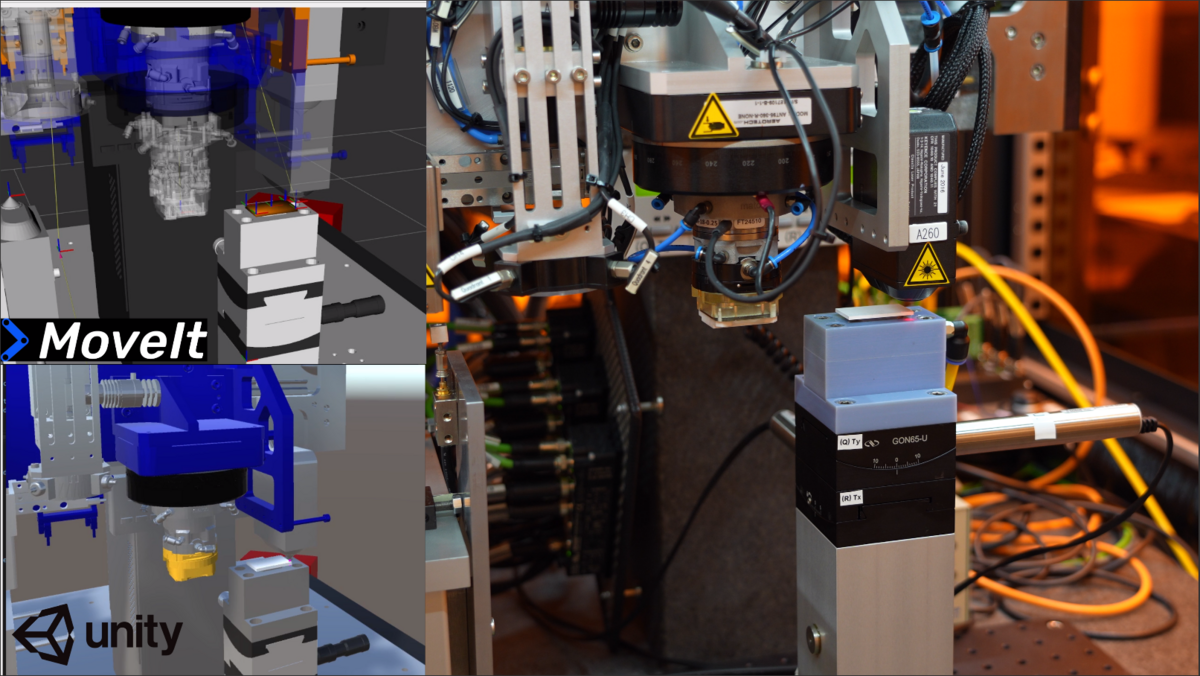

In precision assembly, components are assembled with an accuracy of a few micrometres. Typical fields of application are products in medical technology, micromechanical systems (MEMS) and optical systems. Conventional robots and connected peripherals reach their limits with such high precision requirements. The Institute of Assembly Technology develops novel assembly strategies and processes to meet these high requirements.

One focus of the match's research activities is the development of bonding processes since bonding significantly influences the assembly process and product quality. For example, adhesive shrinkage significantly affects assembly accuracy, and the combination of adhesive and curing parameters determines the bonded joint's strength and the process's cycle time.

Another focus is developing novel handling systems, including fixtures for manual precision assembly tasks and fully automated solutions. One approach uses a magnetic levitation system, in which a workpiece carrier is used simultaneously for workpiece transport and precise component manipulation in the micrometre range. This is, therefore, ideal for use in an in-line production system and for linking different processes. Another decisive factor in linking is the consistency of the process data. Here, the match researches self-optimizing processes by merging simulation, development and manufacturing data into a virtual model of the entire assembly system.

In the research area of self-assembly, the match is concerned with developing self-positioning systems so that high-precision handling systems are no longer necessary for precise assembly.

Contact: Martin Stucki, Rolf Wiemann, Niklas Terei, Lars Binnemann